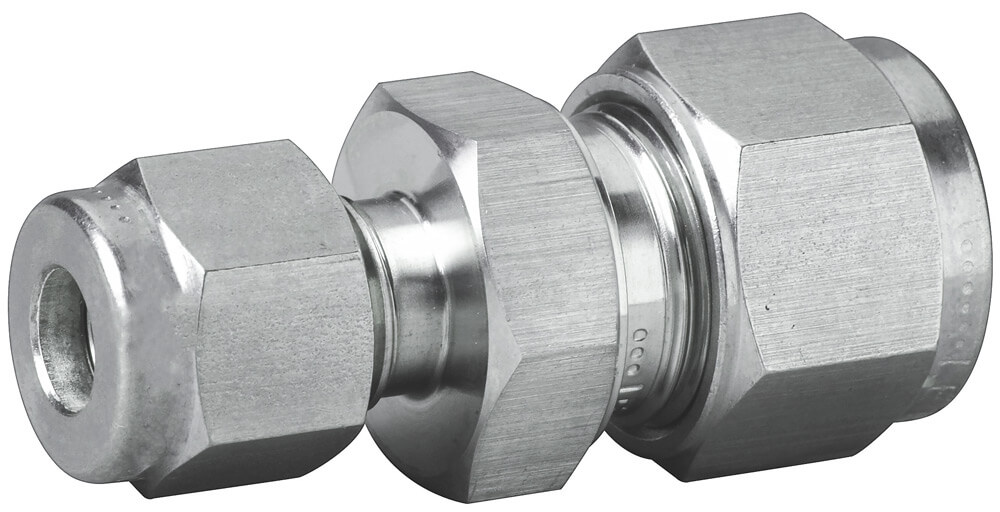

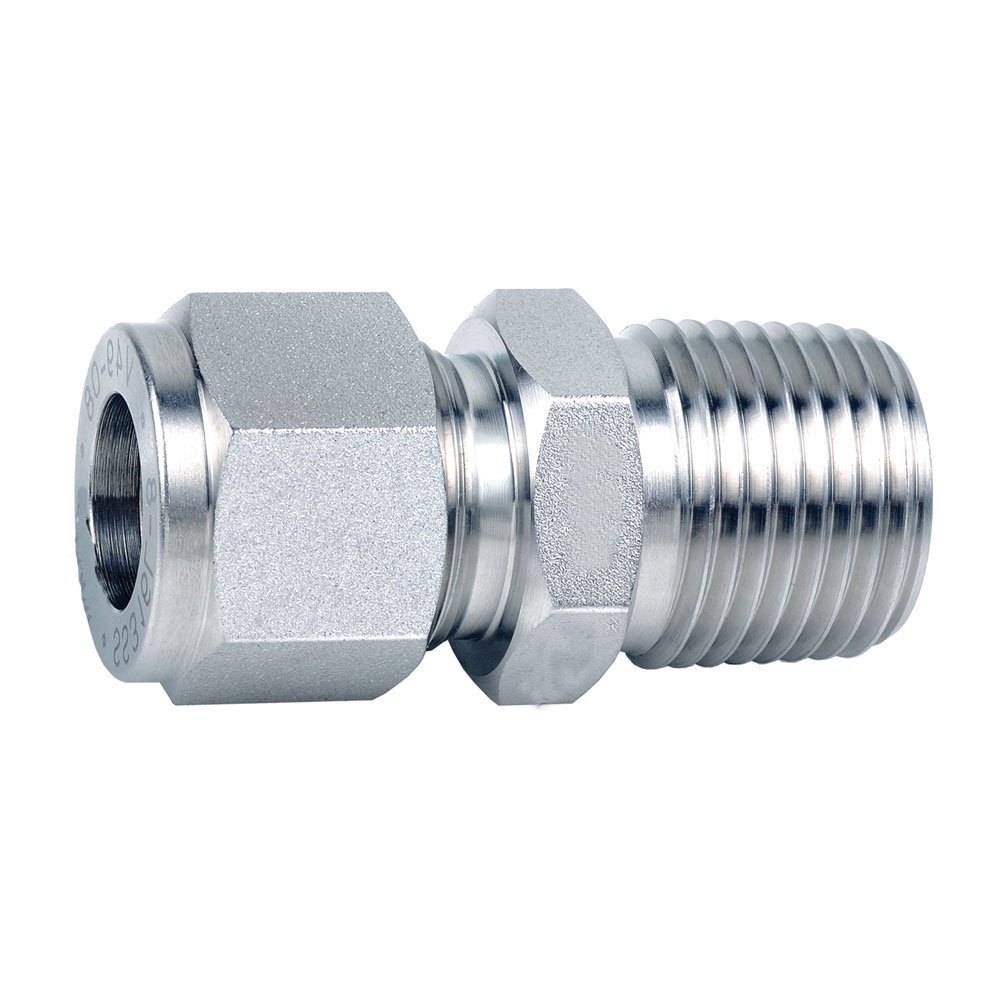

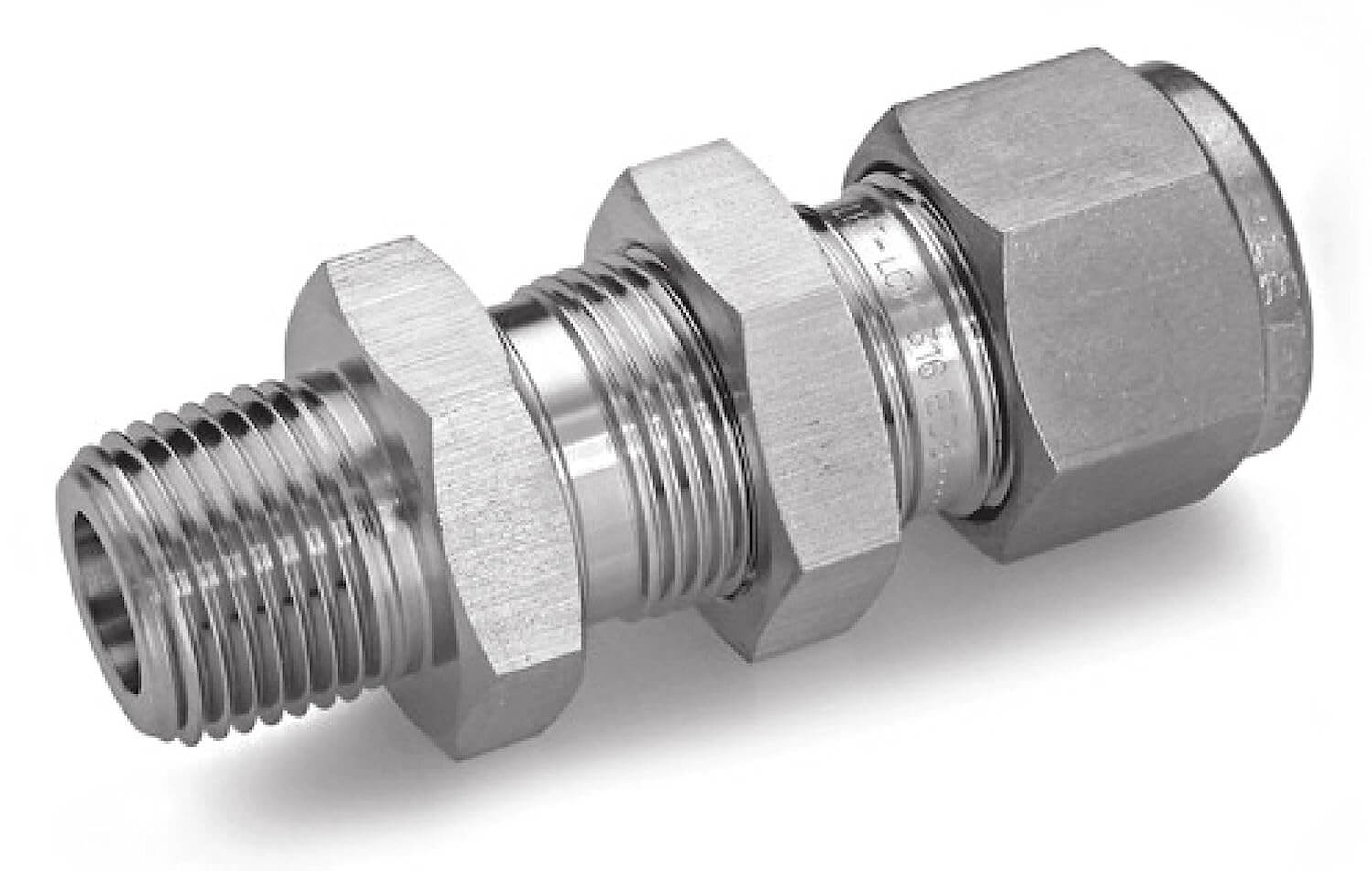

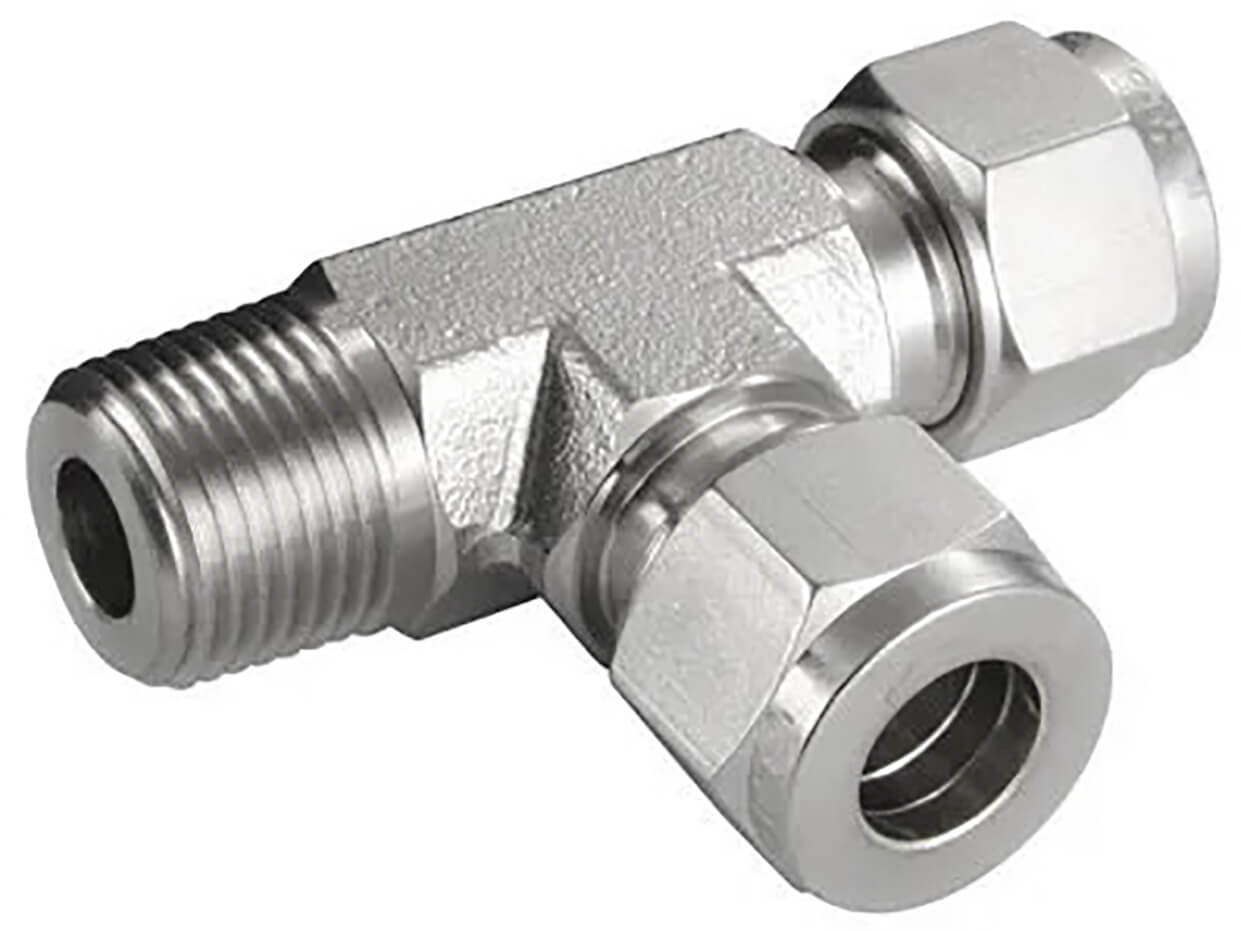

Double Ferrule Tube Fitting

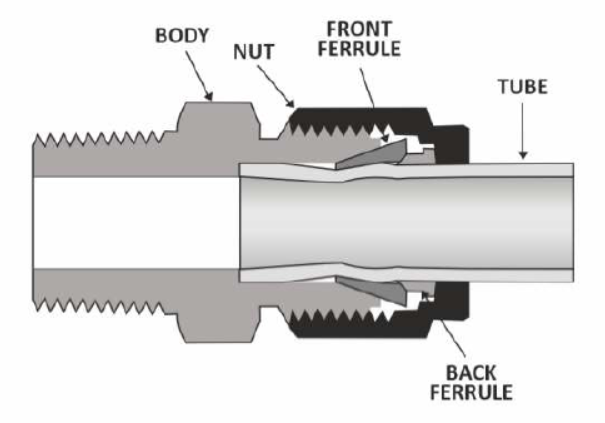

Flowsys manufactures double ferrule compression tube fittings for instrumentation & fluid transmission system to provide torque free & leak proof joints at all tubing connection & hence prevents costly and hazardous leaks in process & instrumentation tubing. Flowsys double ferrule tube fittings consist of four precision engineered components called the body, nut, front ferrule & back ferrule, all manufactured to very stringent tolerances under rigid quality control procedures. When installed affixed to tubing becomes a five-piece connection provide a solid leak proof joint by the sequential action of twin ferrule which is a combination of geometry & metallurgy.

Flowsys double ferrule tube fittings are easy to install & does not require any

special tools. These fittings are used several times with no damage on tube and fittings. We summarize some of the silent feature below.

PErformance

- Work on low as well as high pressure.

- Work on low as well as high temperature rated for tubes.

- Work without leakage up to burst point.

- Seals continuously under make & break condition.

Design

- Torque free design because of axial movement rather than rotary movement.

- Self-Aligning

- Vibration Resistance.

- Thermal Compatibility & Corrosion Resistance.

- Resistance to temperature cycle.

- Unique combination of Geometry and Metallurgy.

Product Range & Technical Specification

Size | Fraction | 1/8" Tube OD to 1.1/2" Tube OD | |

Metric | 3mm Tube OD to 38mm Tube OD | ||

Pressure | 4000 psi to 10000 psi depends upon size (Please reffer size chart) | ||

Temprature | Upto 648 Degree Celsius | ||

End Connection | Available with NPT, BSPT, BSPP, SAE Pipe Threads or any other type upon request | ||

Material | SS316/SS304 | Inline | ASTM A276 / ASTM A479 |

Forging | ASTM A182 | ||

Carbon Steel | Inline | ASTM A108 | |

Forging | ASTM A105 / ASTM A106 | ||

Also available in Brass, Monel, & Special Alloy in | |||