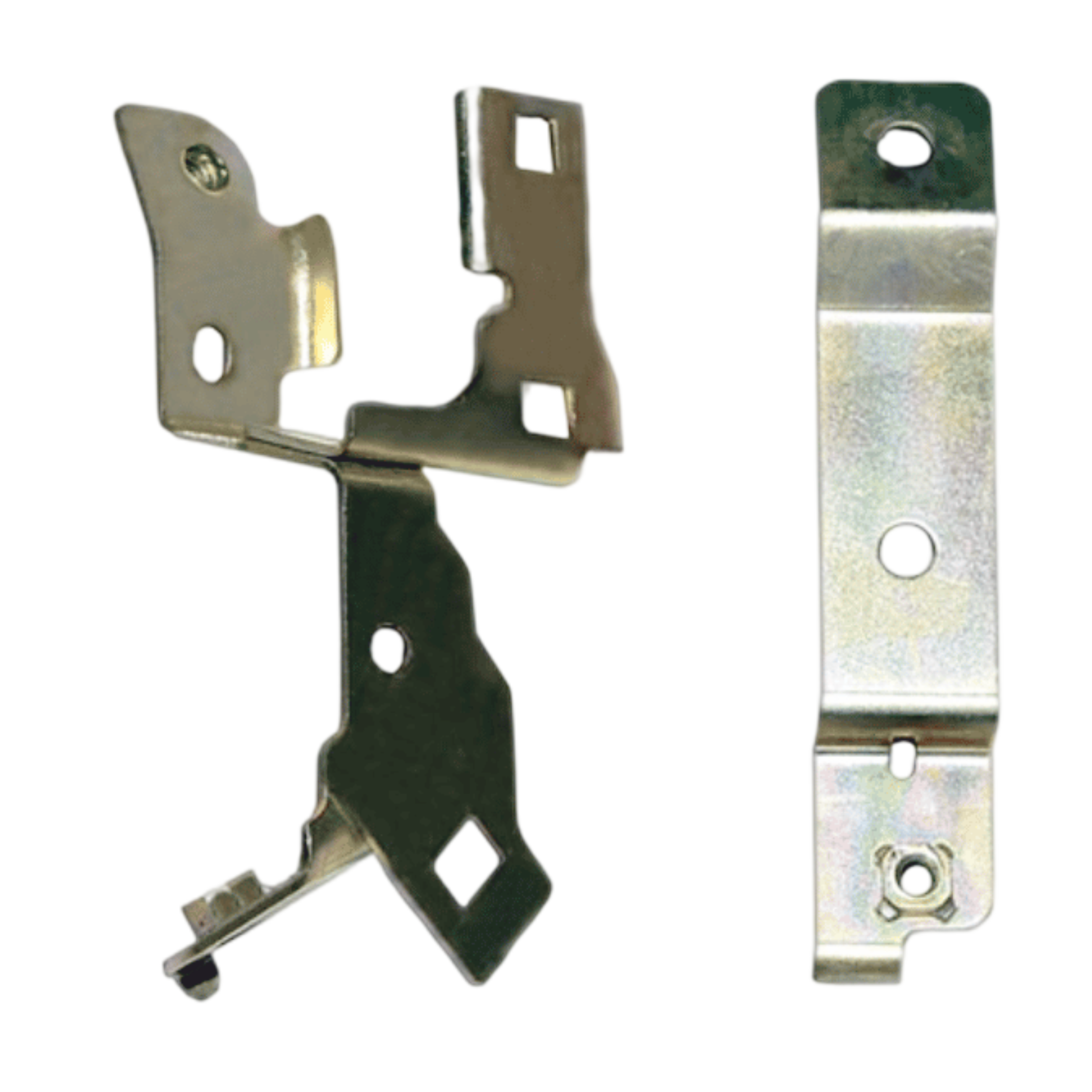

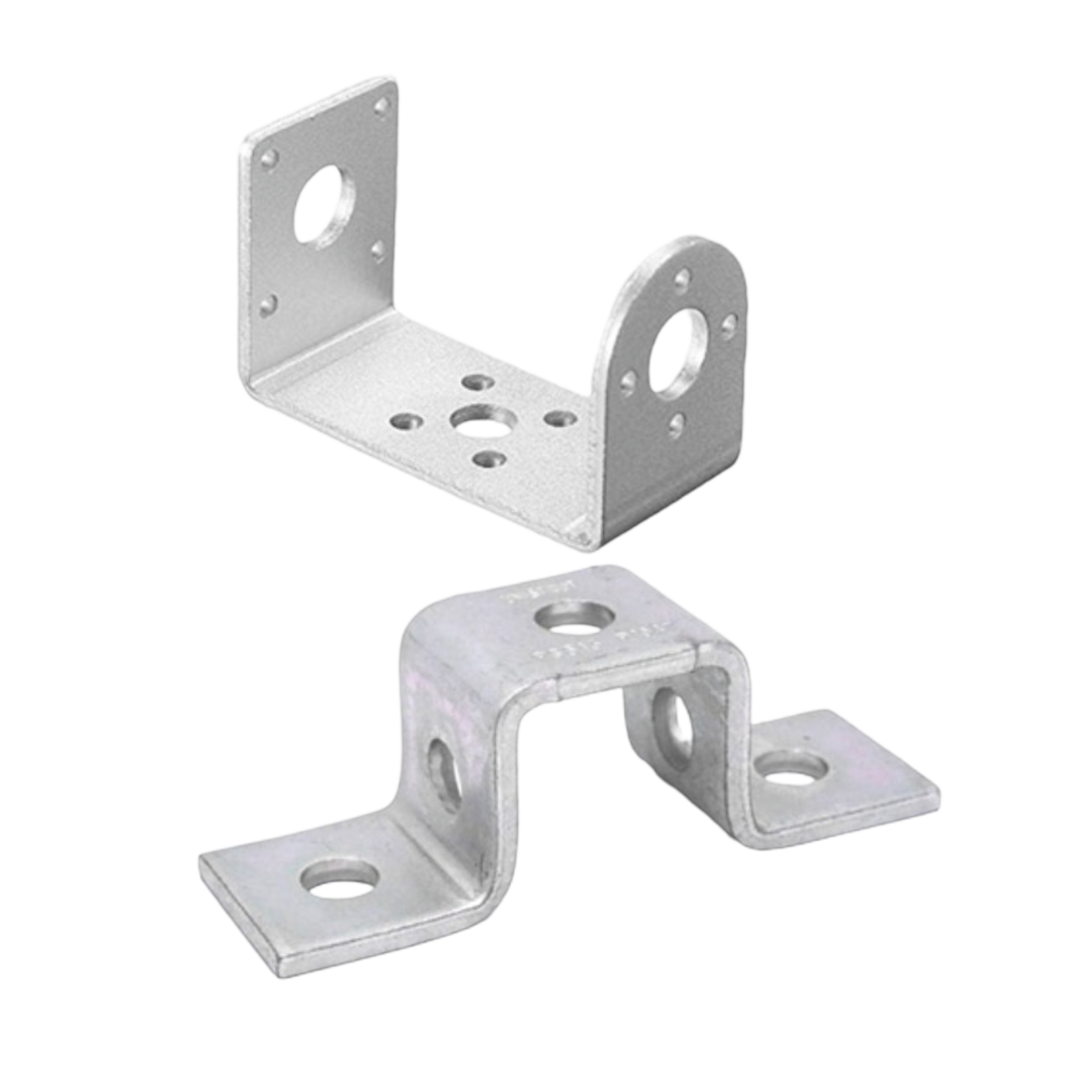

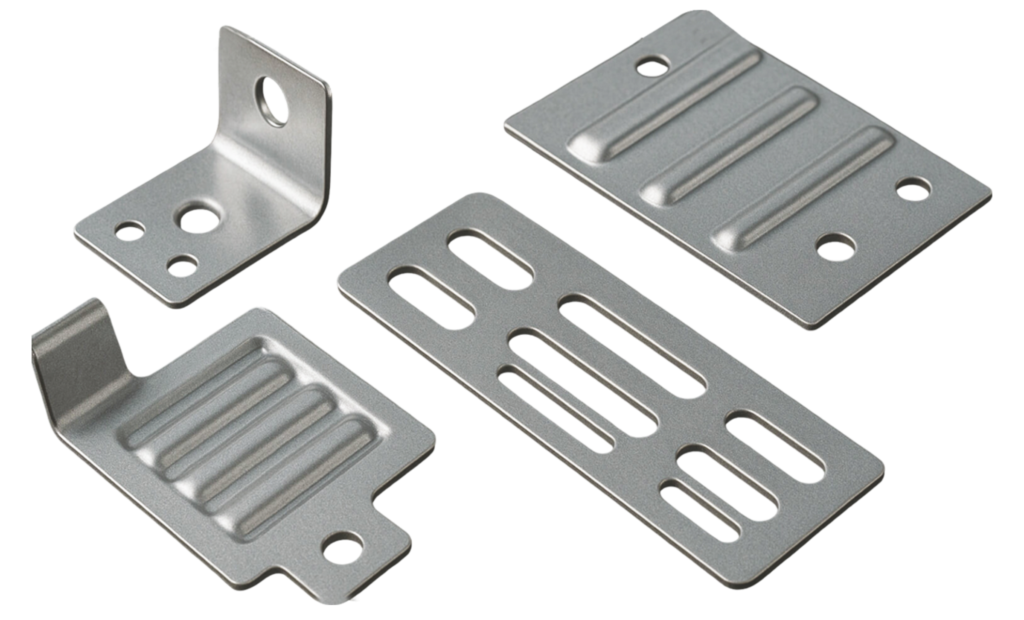

Sheet Metal Components

Sheet metal components are parts made from flat sheets of metal, typically steel, aluminum, that are cut, bent, and formed into specific shapes.

These components are fundamental to countless industries due to their high strength-to-weight ratio, durability, and cost-effectiveness.

The manufacturing process, known as sheet metal fabrication, uses a variety of techniques to transform the raw material into finished products.

Fabrication Processes

- Cutting: The initial step where the sheet metal is cut to the required size and shape. Common methods include laser cutting, which offers high precision for intricate designs; waterjet cutting, ideal for materials sensitive to heat; and shearing, which uses a large blade to cut the metal in a straight line.

- Forming: This is the process of shaping the cut metal without removing material. Bending using a press brake is a primary method for creating V-shapes or U-channels. Stamping, which uses a punch and die to deform the metal, is another popular technique for creating complex shapes in high-volume production.

- Joining: Pieces are assembled to form the final product. Welding is a common method for creating strong, permanent bonds.

- Finishing: The final step to improve the component’s durability and appearance. This can include powder coating, anodizing, or electroplating to add color and corrosion resistance.